Bore Tech CU+2 Copper Remover Bore Cleaner

25.51€ – 45.97€Price range: 25.51€ through 45.97€

100% secure payment

Quality control

Patented, ammonia-free copper remover. Fast-acting, barrel-safe, and odorless.

Bore Tech Cu+2 Copper Remover – Patented Ammonia-Free Copper Fouling Solution

Eliminate copper fouling safely and effectively with Bore Tech’s patented Cu+2 Copper Remover™. This revolutionary two-step chemistry dissolves copper deposits faster and more completely than traditional ammonia-based solvents, without the harsh fumes, toxicity, or barrel damage risks. The advanced formula removes even extreme copper buildup from match-grade barrels while being 100% barrel safe, odorless, and environmentally responsible – making it the preferred choice of competitive shooters, gunsmiths, and precision rifle enthusiasts worldwide.

Why Choose Cu+2 Copper Remover?

Traditional copper removers rely on harsh ammonia that creates toxic fumes, corrodes barrel steel with extended contact, and requires extensive ventilation. Bore Tech’s Cu+2 uses patented chelating technology that bonds with copper at the molecular level, lifting it from the bore without damaging the underlying steel. The two-step process works faster than conventional solvents – you’ll see blue patches immediately, indicating aggressive copper removal. Unlike ammonia-based cleaners that can etch barrels if left too long, Cu+2 can soak overnight without risk, making it perfect for removing stubborn copper from precision rifle barrels where accuracy depends on a pristine bore.

Key Features:

- Patented Two-Step Chemistry: Unique formula dissolves copper faster and more completely than traditional single-step solvents

- 100% Ammonia-Free: No toxic ammonia fumes, safe for indoor use without ventilation concerns

- Completely Odorless: Zero offensive smell during application or use

- 100% Barrel Safe: Non-etching, non-corrosive formula safe for all barrel steels including stainless, carbon steel, and chrome-lined

- Rapid Copper Extraction: Aggressive copper removal shows blue on patches immediately

- Safe Extended Contact: Can soak overnight without barrel damage – perfect for extreme copper buildup

- Short-Term Rust Prevention: Provides temporary corrosion protection after cleaning

- Biodegradable Formula: Environmentally responsible, water-based chemistry

- Non-Hazardous: No special handling, storage, or disposal requirements

- User-Friendly: Simple application process with visible results

- Professional Grade: Trusted by benchrest shooters and firearms manufacturers

Technical Specifications:

- Available Sizes: 4 oz, 16 oz (1 pint), 32 oz (1 quart)

- Formula Type: Patented two-step chelating copper solvent

- Chemical Composition: Ammonia-free, water-based

- Odor Level: Zero – completely odorless

- pH Level: Neutral (barrel safe)

- Hazard Classification: Non-hazardous, non-toxic

- Compatibility: All barrel steels – stainless, carbon steel, chrome-lined, button rifled, cut rifled

- Finish Safe: Parkerizing, bluing, Cerakote, nitriding, anodizing, nickel boron

- Biodegradable: Yes – environmentally friendly

- VOC Compliant: Meets all environmental regulations

- Shelf Life: Extended stability with proper storage

- Country of Origin: Made in USA

Performance Benefits:

- Faster Cleaning: Two-step chemistry removes copper in less time than traditional ammonia solvents

- Safer to Use: No toxic fumes, no ventilation required, safe for prolonged skin contact

- Better Results: Removes deeply embedded copper conventional cleaners leave behind

- No Barrel Damage: Safe for overnight soaks on stubborn copper – won’t etch or corrode like ammonia

- Indoor Friendly: Odorless formula enables cleaning anywhere without ventilation

- Preserves Accuracy: Complete copper removal maintains consistent bore dimensions for precision shooting

- Extends Barrel Life: Gentle formula won’t accelerate throat erosion or barrel wear

- Prevents Accuracy Loss: Regular use prevents copper buildup that degrades accuracy

- Environmentally Responsible: Biodegradable formula reduces environmental impact

Application Guide:

Step-by-Step Copper Removal:

- Ensure Safety: Verify firearm is unloaded and safe

- Remove Carbon First: Use Bore Tech C4 Carbon Remover to eliminate carbon fouling (copper removers work best on clean carbon-free bores)

- Saturate Patch or Brush: Wet bore brush or cleaning patch thoroughly with Cu+2

- Run Through Bore: Push saturated brush/patch through bore 3-5 times

- Allow Dwell Time: Let soak 10-15 minutes for moderate copper, overnight for extreme buildup

- Observe Results: Push dry patch through – blue color indicates copper removal

- Repeat Process: Continue Cu+2 application and patching until patches emerge clean (no blue)

- Final Patches: When patches come out white/clean, bore is copper-free

- Light Oiling: Cu+2 provides short-term rust prevention, but apply gun oil for long-term storage

- Ready to Shoot: Bore is clean and ready for shooting

For Extreme Copper Fouling:

- Apply Cu+2 generously to bore

- Seal bore ends with patches to prevent evaporation

- Let soak overnight (safe for extended contact)

- Next day, run wet brush through bore

- Push patches through until clean

- Repeat if necessary for very heavy buildup

Maintenance Cleaning Schedule:

- Match/Precision Rifles: Every 50-100 rounds or when accuracy degrades

- Hunting Rifles: After range sessions or annually before season

- High-Volume Shooters: Every 200-300 rounds to prevent heavy buildup

- Break-In Period: After every 5-10 shots during new barrel break-in

Ideal Applications:

- Precision Rifle Barrels: Match-grade barrels where bore condition directly affects accuracy

- Benchrest Competition: Where minute accuracy improvements matter

- F-Class & Long Range: Maintaining consistent velocities through copper-free bores

- New Barrel Break-In: Gentle formula ideal for frequent cleaning during break-in process

- Hunting Rifles: Seasonal maintenance to restore accuracy

- AR-15/AR-10 Barrels: Regular maintenance for semi-auto platforms

- Pistol Barrels: High-volume competition guns with copper buildup

- Gunsmithing: Professional cleaning before chambering, crowning, or accuracy work

Understanding Copper Fouling:

Every bullet fired deposits microscopic copper particles in the barrel. Over time, this copper accumulation:

- Reduces Accuracy: Changes bore dimensions causing velocity variations and group size increases

- Increases Pressure: Restricts bore diameter raising chamber pressures

- Degrades Consistency: Uneven copper deposits create inconsistent bullet release

- Accelerates Wear: Copper buildup increases friction and heat, accelerating throat erosion

- Compounds Over Time: Each shot adds more copper, making removal progressively harder

The blue color on patches when using Cu+2 is dissolved copper being extracted from the bore – visual proof that cleaning is working.

Cu+2 vs. Traditional Ammonia Cleaners:

| Feature | Bore Tech Cu+2 | Ammonia-Based Cleaners |

| Odor | Zero – completely odorless | Strong ammonia fumes |

| Toxicity | Non-toxic, non-hazardous | Toxic ammonia vapors |

| Barrel Safety | Safe for overnight soaks | Can etch/damage with extended contact |

| Speed | Fast – shows blue immediately | Slower action |

| Indoor Use | Safe anywhere | Requires ventilation |

| Environmental | Biodegradable, water-based | Petroleum solvents |

| Completeness | Two-step chemistry – more thorough | Single-step – may leave residue |

Pro Tips for Maximum Effectiveness:

- Remove Carbon First: Always clean carbon before copper – C4 Carbon Remover followed by Cu+2 works best

- Use Nylon Brushes: Bronze brushes can false-positive copper readings; use nylon for accurate results

- Wet the Bore Well: Generous application ensures complete copper contact

- Be Patient: First few patches will be dark blue; keep going until patches are clean

- Overnight Soaks: For stubborn copper, seal bore ends and let Cu+2 work overnight

- New Barrels: Expect heavy copper during break-in – clean frequently for first 50-100 rounds

- Track Round Count: Clean before accuracy degrades, not after

Two-Step Chemistry Explained:

Cu+2’s patented formula works through a two-step molecular process:

- Step 1 – Chelation: Active ingredients bond with copper atoms at the molecular level

- Step 2 – Extraction: Bonded copper is lifted from the steel and suspended in solution

This process is faster and more complete than simple chemical dissolution used by traditional cleaners, resulting in cleaner bores with less effort.

Compatible Bore Tech Products:

For complete barrel maintenance, use Cu+2 with:

- Bore Tech C4 Carbon Remover: Remove carbon before copper for best results

- Bore Tech Eliminator: All-in-one cleaner for combined carbon and copper removal

- Bore Tech Proof-Positive: Final bore conditioning and protection

- Bore Tech Friction Guard XP: Premium firearms lubricant

Storage & Handling:

Store Cu+2 Copper Remover in a cool, dry place away from direct sunlight. Keep container tightly closed when not in use. No special storage requirements or hazmat handling needed. Product remains effective for years with proper storage. Safe to transport and ship via standard carriers.

What’s Included:

- Bore Tech Cu+2 Copper Remover (size as selected)

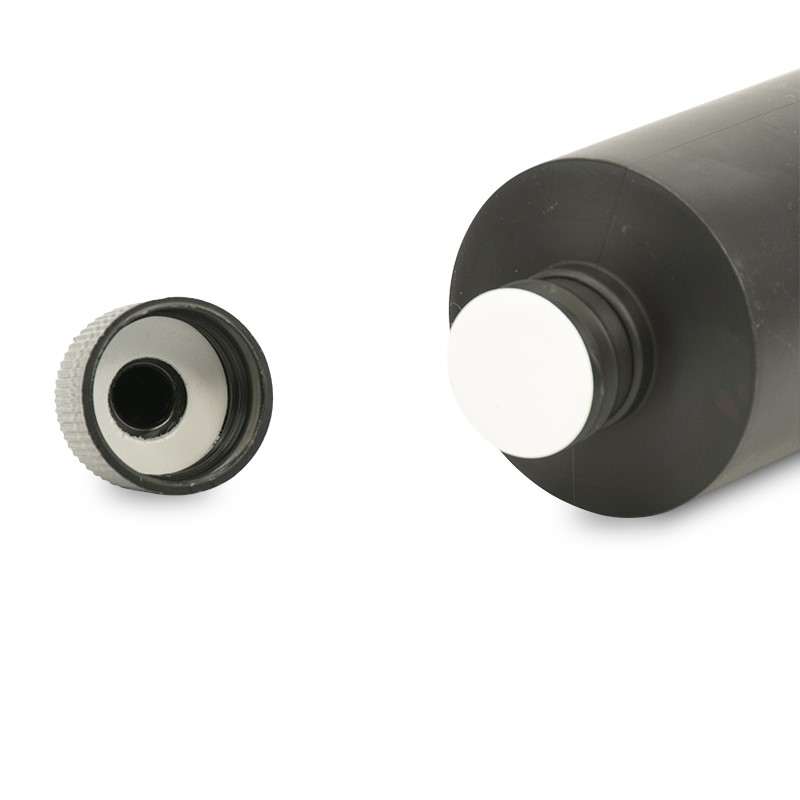

- Precision dispensing cap for controlled application

- Detailed usage instructions

| Size | 04 Oz / 120 ml, 16 Oz / 470 ml |

|---|

Related products

POPULAR

NOVENTLY

POPULAR

NOVENTLY

POPULAR

NOVENTLY